Sectional Doors

Sectional Doors & Door Parts.

Sectional Doors

Composition

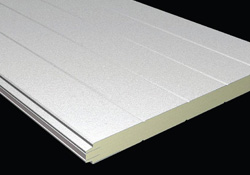

Outer and Inner Sheet:

Core:

Seal:

Thermal Performance

Colours & Finishes

Outer Skin:

Inner Skin:

The outer skin is finished and coloured to match most contemporary bu

The internal liner skin is finished in RAL 9010 white, polyester coated, stucco embossed galvanised steel as standard.

A separate list and sample swatch of the current colour range is available up on request.

ilding cladding. Please see separate leaflet for range of finishes and colours.

Thermal Bow

It should be noted that when a door is due to be positioned where it is likely to receive direct sunlight then dark colours should be avoided due to the potential of thermal bow. Contact us for further information.

Acoustics

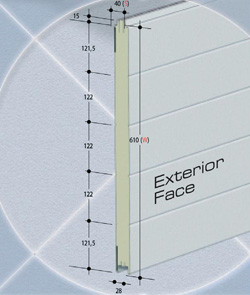

The 40mm insulated door panel gives sound reduction of (Rw) 25db. Please note; this is for the panel only, and does not include joints, i.e. a fully installed door.

Panel Options & Accessories

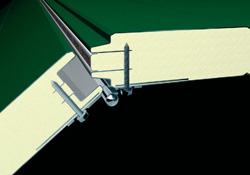

A range of windows in various sizes can be incorporated in the panel, the standard being 600 x 300mm with radiused corners. Each panel is fitted with pre punched galvanised steel end caps and the top and bottom panels are finished with an aluminium retainer which holds the top and bottom EPDM seals.

A range of locking options are available.

Wicket doors are available 800 x 1800mm approx. 150mm above floor level, supplied complete with cylinder type locking.

Our Sectional Overhead Doors are manufactured in accordance with the requirements of the harmonised European Standards BSEN 13241-1:2003

NOTE: It is our policy to supply doors that meet all relevant Building Regulations and Health & Safety Requirements, wherever it is practical and we urge our customers to familiarise themselves with their onward obligations. For further information please contact us.

Door Parts

Tracks

- Individually designed for each door

- Fully galvanised

- Bolted and riveted or spot welded

Options Include:

- All tracks supplied with 3m lengths of punched installation angle and side seals

Springs & Hardware

- Individually designed for each door

- Highest grade springs to DIN 17223 Sort C specification for longer life

- Fully keyed shaft with adjustable coupler

- Spring break device supplied as standard

- Drums, end bearing plates, centre bearing plates, PVC spring fillers (152mm diameter springs only), plugs & winders, securing bolts

- All components galvanised for weather protection

- Doors supplied with adjustable side hinges, intermediate hinges, nylon rollers, cable sets, bottom corner brackets, spring bumpers, self tapping panel fixings

Operation

- Manual doors can be push-up (up to 3000 x 3000mm) or Chain Hoist driven

- Electric 3ph or 1ph operators available complete with starter and torque bracket

- A range of safety systems available. Cable break and spring break devices are supplied as standard

Proactive Maintenance Programme

Looking to reduce repair costs? Check out our Proactive Maintenance Programme. Regular maintenance of loading bays ensures the safty of operators, extends longevity of the equipment and minimises downtime. We offer preventative maintenance service contracts to reduce ongoing maintenance & repair costs and minimise operational downtime. Read more…

Proactive Maintenance

Programme

Request a call back